Save money. Reduce waste. Improve patient care. These are all actions that every department at CCH is being asked to achieve or improve upon—every day. So, where does one start?

Well, the Emergency Department (ED) was able to take a step in the right direction by doing one simple task: standardizing rooms.

“In the department’s last evaluations, I saw that we had low scores across the board, it seemed like there was a lot of waste in my department, and I needed more control over my budget,” says Monte Haddix, ED manager. “I know that I have a great team, so I challenged them to improve.”

The department came together, formed a committee and also took a Lean class with Bud Lawrence, Quality. (For those who don't know, Lean is an approach to improving the delivery of value to customers, through clarifying value-adding versus wasteful actions; and removing the waste.) Committee members included Jari Bachmann, Beth Bowen (who has since moved), Dr. Marion Colburn, Julie Piercy, and Jacque Williams. As they started the LEAN process, the committee found:

- room supplies were in several different areas throughout the department, making nurses and doctors go several places to find what they needed for patients

- there wasn’t a system in place to re-stock depleted supplies – sometimes a tech restocked, sometimes a nurse restocked, and sometimes no one restocked, which left no supplies in the room

- there was no way to know how many items were needed in each room, and where they should go, which made ordering nearly impossible because you didn’t know how much of what product was in each room

- there were often multiple kinds of the same supply, such as alcohol swabs, creating a lot of excess product

With the issues in hand, the committee took on the task of making the improvements. What they did was:

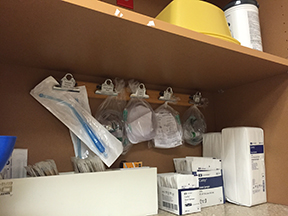

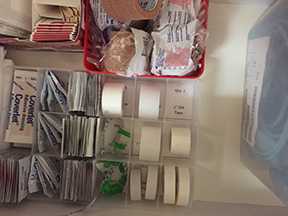

- organized locations where product back stock were to be stored

- created a schedule for items to be restocked, as well as scheduled the task to specific team members

- created reference cards for location and quantity of products needed in each room – complete with pictures

- identified and eliminated excess products

“I was a bit hesitant of making a change because, but once we were developing the process and seeing the changes work, I could see how much is was helping to improve our department,” says Jacque.

While the committee was implementing the changes, they also trained ED staff and asked them to sign contracts saying that they would use the tools provided.

Staff is also pleased with the results. “Nurses don’t have to walk thousands of extra steps a day to find items and the usable products are more accessible—everything is organized and easy to find,” says Julie.

“By simply standardizing our rooms, we have been able to reduce waste and save money—my budget is now in the black, instead of the red. And, as an added bonus, we’ve been able to provide more efficient patient care because staff isn’t wasting time looking for items they need,” says Monte.